참고문헌

[1] Applied Surface Science 264 (2013) 761–766

[2] Basics of Microstructuring: DEVELOPMENT

[3] Volume 37, Issue 6, June 2006, Pages 519-525

[4] Volume 80, Issue 2, 10 March 2000, Pages 179-188

[5] DOI: 10.1109/MHS.1998.745752

[6] DOI: 10.1109/MEMSYS.1999.746845

[7] Dutta, S., Imran, M., Kumar, P. et al. Comparison of etch characteristics of KOH, TMAH and EDP for bulk micromachining of silicon (110). Microsyst Technol 17, 1621 (2011). https://doi.org/10.1007/s00542-011-1351-6

[8] Anisotropic etching in low-concentration KOH: effects of surfactant concentration

[9] The fabrication of silicon nanostructures by focused-ion-beam implantation and TMAH wet etching

[10] Pal, P., Swarnalatha, V., Rao, A.V.N. et al. High speed silicon wet anisotropic etching for applications in bulk micromachining: a review. Micro and Nano Syst Lett 9, 4 (2021). https://doi.org/10.1186/s40486-021-00129-0

[11] A detailed investigation and explanation of the appearance of different undercut profiles in KOH and TMAH

[12] Difference in Activated Atomic Steps on (111) Silicon Surface during KOH and TMAH Etching

0. Introduction

Aqueous Alkaline Developers

시장에 나와있는 positive, negative resists는 주로 developed aqueous-alkaline이다. 이러한 resist에 맞는 developer는 희석된 NiOH, 또는 KOH를 구성으로 하는 solution을 기반으로 하거나, 또는 metal-ion-free 유기 TMAH (TetraMethylAmmoniumHydroxide)의 aqueous solution으로 이루어져 있다.

많은 developer는 $CO_2$에 의한 중성화를 막는 chemical buffer를 이용하여 사용기한을 늘리며, surface wetting agents를 이용하여 puddle development를 야기하고, 없애기 힘든 resist 잔여물을 제거하기 위한 첨가제를 추가한다.

Developer 용기가 한번이라도 열리면 고립된 곳에 잘 보관되어야 하며, 불필요하게 오래닛간동안 뚜껑이 열리면 안된다. 이는 대기 중 CO2가 용액에 들어가는 것을 방지하기 위함이다. CO2는 developer의 행동을 억제하며 after exhaustion of a possible chemical buffer and reduces its rate of development by decreasing the pH value and thus its activity.

Open containers filled with developers also absorb CO2 from the ambient air, where the ratio of surface to volume is decisive: Beakers should be changed at least daily, while larger tanks can remain stable for days and weeks. When the developer is protected by a nitrogen curtain in the process pauses, which is placed on the developer surface like a carpet, thus suppressing the CO2 input, the shelf life is significantly increased.

potassium hydroxide (KOH)

tetra-methyl ammonium hydroxide (TMAH) (organic hydroxide)

Out of all the hydroxides, KOH etches the nicest.

This fact explains the difference in macroscopic anisot ropy in KOH and TMAH etching in the vicinity of (111).

표면 결정의 etch rate의 방향 의존성은 서로 다른 두개의 etchants에 대해 상당히 다르다. (특히 (111) plane과 (221) plane에서). 우리는 두개의 etchant가 이 두 plane을 포함하는 영역에서 만큼은 서로 다른 etching mechanism을 갖고 있는 것으로 결론내려다. Etching rate는 KOH에서는 25 wt.%을, TMAH에서는 20 wt.%를 가진다.

KOH와 TMAH에서의 활성에너지는 (100), (110), (320) plane에서는 거의 동일하였지만, (221), (111) plane에서는 달랐다. Etchant의 순환은 희석된 TMAH solution에서의 etching rate는 매우 큰 효과를 나타냈지만, KOH solution에서는 큰 효과를 발휘하지 못했다. KOH속 (100) plane에서의 roughness는 TMAH의 것 보다 한 오더 정도 더 작은것으로 나타났다.

Hello Mattieu,

IMHO, from a health perspective, TMAH appears far more dangerous than KOH. We

recently prepared a lab-wide notification concerning TMAH and its known but often

overlooked dangers based on skin adsorption as opposed to ingestion as an

identified

route of exposure.

"Materials Safety Bulletin

September 24, 2010

TMAH: New Hazard Awareness Concerning an Old Chemical

Tetramethylammonium hydroxide (TMAH) is widely used in micro- or nanofabrication

as an etchant and developer. In MSD, TMAH is typically one of several

ingredients in

commercial etching/stripping mixtures, although it may also be used as a pure

chemical.

While it has long been known to be very toxic if ingested, recent industrial

experience

indicates that skin exposure may result in serious injury/illness or even death.

Since 2007,

there have been 3 recorded fatalities from skin exposure to TMAH solutions as

dilute as

25%. Two of the recorded fatalities occurred due to heart attack despite immediate

decontamination and prompt medical care. Thus skin, exposure to >1% TMAH over a

few percent of the body must be treated as a life-threatening event. MSDSs may

be out of

date and not properly describe this high dermal toxicity.

When handling this material, the minimum set of personal protective equipment

includes:

safety goggles (not glasses), disposable nitrile gloves, a buttoned lab coat,

leg covering and

closed-toe shoes. The disposable gloves may only provide brief protection and

must be

replaced if they become wetted. More protective gloves are the Stansolv or

Tri-Ionic glove

models sold by MAPA.

In the event of a splash, contaminated clothing must be removed and the wetted area

thoroughly washed with soap and water, using the emergency shower if necessary.

Call 911 and summon emergency medical help.

You should not handle TMAH containing materials when working alone.

Tri-Ionic clean room gloves provide excellent protection from TMAH exposure."

David A. Bunzow

User Facilities Program Manager

The Molecular Foundry

Materials Science Division

Lawrence Berkeley National Laboratory

1 Cyclotron Road MS 67-3207

Berkeley, CA 94720

Office: 510-486-4574

FAX: 510-486-7424

Cell: 701-541-2354

On 5/18/2011 9:20 AM, Matthieu Nannini, Dr. wrote:

> Dear all,

>

> Having only one base dedicated bench running TMAH @ 85C I have now to make a choice between TMAH and KOH since new researcher are asking for KOH. Maintaining the 2 chemicals requires resources that I don't have.

> Process wise, TMAH is better with oxide masks but KOH is better with SiN masks. KOH also etches faster and nicer.

> My questions are in terms of safety: could you share your experiences with KOH vs TMAH in terms of ease of use, safety, etc...

>

> Thankshttps://mtl.mit.edu/pipermail/labnetwork/2011-May/000265.html

[labnetwork] TMAH vs KOH

mtl.mit.edu

Hydrogen silsesquioxane (HSQ) is typically developed in an aqueous alkali solution such as tetramethyl ammonium hydroxide. This development process results in low contrast.

In this work, the authors instead used a mixture of salt and alkali to significantly increase the contrast of HSQ.

Remarkably, this salty developer resulted in contrast enhancement without significant decrease in resist sensitivity.

Recent efforts to increase the contrast of hydrogen silsesquioxane have focused on developing with more concentrated alkalis and elevating development temperatures These development methods showed improved contrast at the expense of reduced sensitivity

- Developer: MF312 (need KOG based ddeveloper)

- Typical dose range 800~3000

- low line edge roughness (LER)

- low line width roughness (LWR)

- Once exposed to the e-beam, it is similar to $SiO_2$ which makes it etch mask for $Si$ etching.

- lower contrast than PMMA

The exposed areas differ chemically from the non-exposed sites. The purpose of the development is to dissolve either the exposed (in the case of positive resists) or the unexposed (in the case of negative resists) resist areas, resulting in the final desired resist structures.

This chapter discusses the basic chemical and physical processes during development and explains the impact of different process parameters on the development rate and selectivity of the development process.

1. Basic Chemistry of Developers

1.1. Aqueous Alkaline Developers

Microchemicals사 측에서 판매하고 있는 positive PR과 negative PR은 일반적으로 developed aqueous-alkaline이다. 이에 따른 developer는 diluted sodium hydroxide, potassium hydroxide, 또는 metal ion free organic TMAH 수용액을 기반으로 한다. 많은 developer들은 화학적 buffer를 사용하는데, 목적과 수단은 다음과 같다.

- 유효기간을 늘리기 위함 : buffer를 사용하여 ��2에 의한 중성화를 막음

- puddle development를 위해 surface wetting agents를 사용

- tenacious resist residues를 없애기 위해 첨가제를 사용.

Opened developer containers should be stored well closed and not left open for an unnecessary length of time in order to prevent the ingress of CO2 from the ambient air. CO2 reduces the activity of the developer after exhaustion of a possible chemical buffer and reduces its rate of development by decreasing the pH value and thus its activity. Open containers filled with developers also absorb CO2 from the ambient air, where the ratio of surface to volume is decisive: Beakers should be changed at least daily, while larger tanks can remain stable for days and weeks. When the developer is protected by a nitrogen curtain in the process pauses, which is placed on the developer surface like a carpet, thus suppressing the CO2 input, the shelf life is significantly increased.

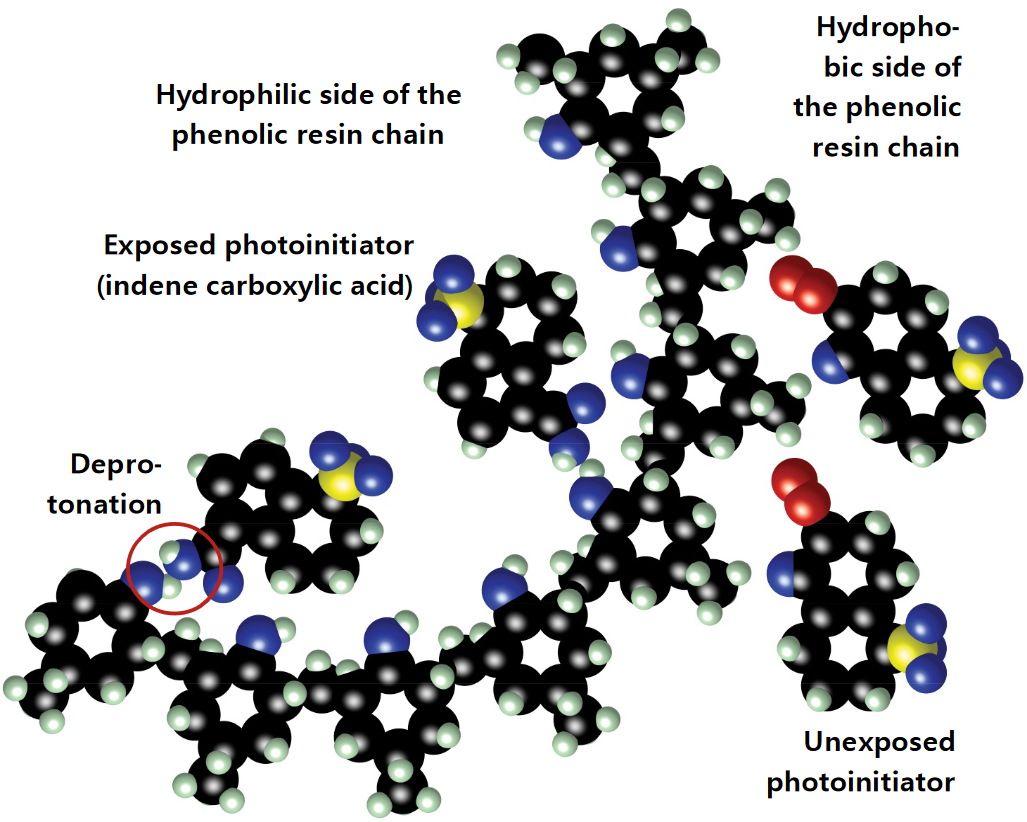

Fig. 96: The schematic process of development of DNQ-based photoresists at the molecular level: In the unexposed state, the photoinitiator is located on the hydrophobic side of the phenolic resin chains, the indene carboxylic acid formed during exposure expands to the hydrophilic side. There, it separates a proton from the resin, which is thereby negatively charged and now soluble in aqueous alkaline developers. Carbon atoms are shown here in black, hydrogen atoms light grey, oxygen atoms blue, nitrogen atoms red, and sulphur atoms yellow.

1.2. Organic Solvents

Cross-linked negative resists can generally also be developed with organic solvents in which the crosslinked resist areas are insoluble. However, caution is advised in the usually aqueous alkaline developable AZ® negative resists which we market, as follows: If the resist is exposed to organic solvents too long, there is a risk that the cross-linked resist areas swell and subsequently separate from the substrate, depending on the degree of cross-linking of the resist film and its adhesion.

23.

2. Selection Criteria of Developers

2.1. Compatibility with Photoresists

lll모든 PR은 residue를 남기기 마련이다. 예를 들어, NaOH 기반의 AZ® 351 developer는 KOH, 또는 TMAH 기반의 developer보다 AZ® 4500을 develop하는데 적합하지 않다. 반면에, AZ111XFS는 AZ303 devloper를 필요로 한다.

If in the processing of negative resists via scattering, diffraction or reflections, an unintended partial exposure of nominally dark resist areas is to be feared, the TMAH-based AZ® 826 MIF can be beneficial. This developer contains an additive for the removal of slightly cross-linked resist areas.

Compatibility with Substrates

The compatibility of the developer with the substrate material used must also be considered: Most developers attack alkaline sensitive metals such as aluminium and copper as well as various compound semiconductors due to their high pH value of approximately 13, which also entails the risk of the etched material being carried over to other sites on the substrate. Our "AZ® Developer" (metal ion-containing, based on sodium metasilicate and phosphate) is optimised for minimal aluminium erosion and also attacks many other alkaline-sensitive materials far less than other aqueous alkaline developers.

Incompatibilities between MIC and MIF Developers Even small traces of TMAH-based metal ion-free developers such as the AZ® 326 MIF, 726 MIF or 826 MIF) can significantly reduce the development rate of metal ion-containing developers (such as the AZ® 400K or 351B). If both types of developers are used, extremely clean work is to be ensured to prevent mutual contamination even in the ppm range, such as in the dispensing system or developer containers

chat GPT

KOH is a strong alkaline developer that is known for providing high contrast and clear differentiation between exposed and unexposed regions of HSQ. It is often preferred when sharp patterning and high contrast are desired.

TMAH, on the other hand, is a milder alkaline developer with higher etch selectivity. It is chosen when a smoother surface with reduced roughness is desired or when finer control over the etching process is required.

In terms of contrast, KOH is generally considered to provide better contrast for HSQ development. It offers a more distinct differentiation between exposed and unexposed areas, resulting in sharper patterns. However, the choice between KOH and TMAH also depends on other factors such as the desired etch selectivity, surface smoothness, and the specific requirements of the HSQ application.

'반도체 공정& 소자 > 기기, 장비, 용액, 측정' 카테고리의 다른 글

| Delta Mode (0) | 2023.03.06 |

|---|---|

| Bias Tee (0) | 2021.08.25 |

| Omnicoat: Adhesion Promoter/Release Layer (0) | 2021.06.28 |

| Photoresist (PR) & E-beam resist (ER) (0) | 2021.06.28 |

| What is Lock-in Amplifier? (0) | 2021.06.10 |

댓글