Lift off using (single layer) negative resist is very challenging for two reasons.

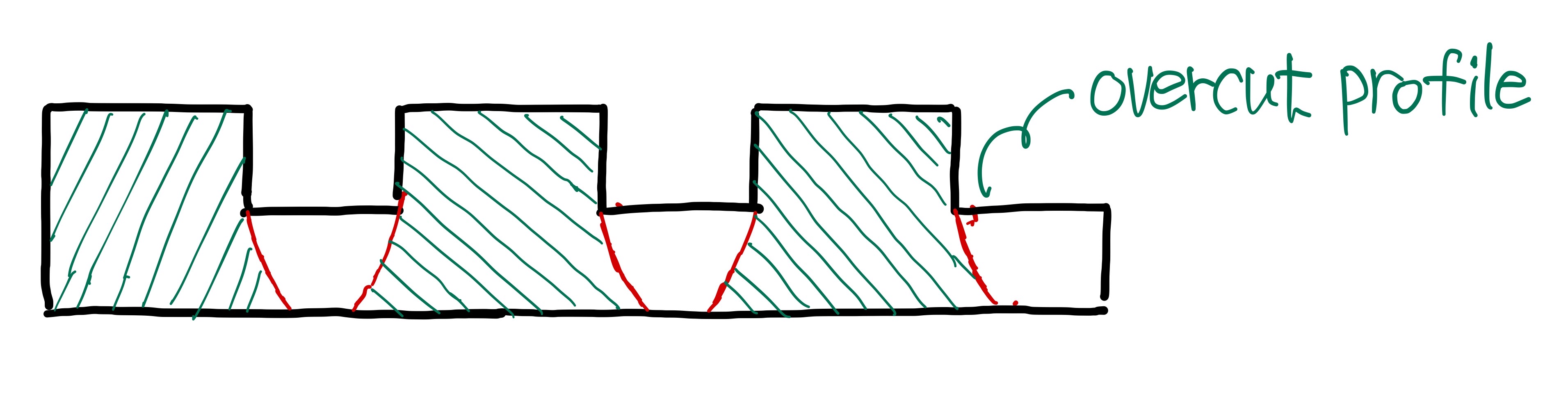

- The resist profile is tapered with wider opening due to electron forward scattering, which leads to film coating on the side wall and thus makes a clean lift off difficult.

- Common negative resists such as polystyrene and SU-8 becomes cross-linked and insoluble upon exposure, and thus a strong chemical must be used to dissolve it, which may attack the metal or sublayer.

How about double layer? → PMMA + HSQ = good (H. Yang et al)

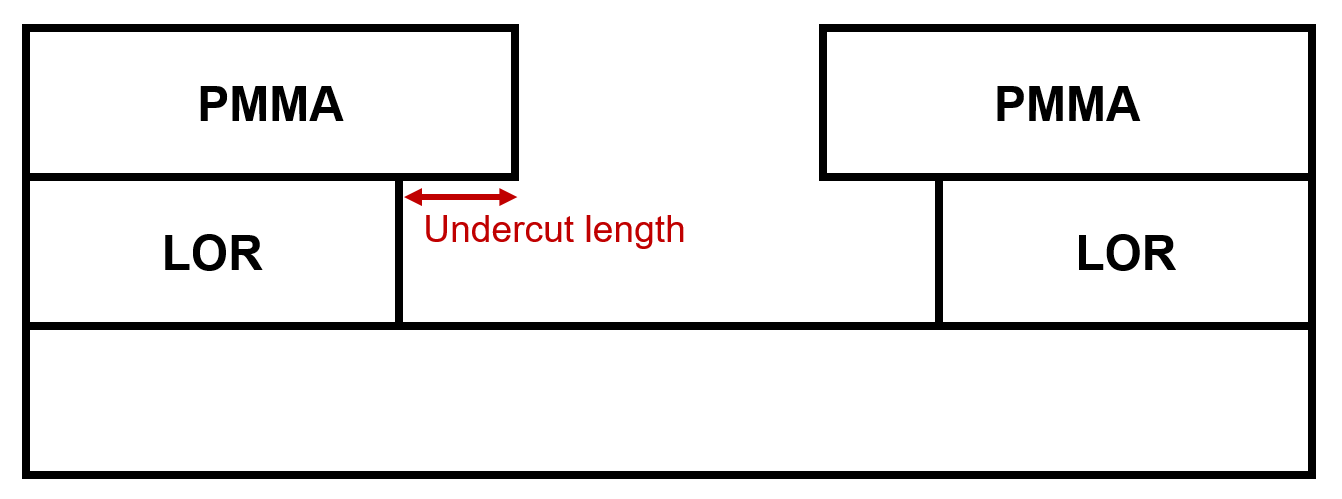

The undercut profiles are highly important in the case of lift-off of isolated features.

In principle, since the sensitivity $\left(\mu C/cm^{2}\right)$ for negative resists like polystyrene is inversely proportional to its number averaged molecular weight, one can achieve an undercut profile using a bilayer with the bottom layer and having a lower molecular wieght (thus less sensitive)

$$ MW \propto \cfrac{1}{sensitivity} $$

If we use bilayer, trilayer

→ The bottom layer is developed faster and it returns in the formation of undercut profile.

Undercut length depends on

- resist thickness

- pre-baking temperature

- concentration and dissolution time of developer

LOR? → Dissolvable in alkali chemicals, and inert to most organic solvents, and solids. (when being baked around its glass transition temperature $189\degree C$

'반도체 공정& 소자 > Etching' 카테고리의 다른 글

| 반도체 공정 Outline (0) | 2022.06.22 |

|---|---|

| Introduction to Electron Beam Lithography (EBL) (0) | 2021.08.25 |

| Lithography - Etching Techniques (0) | 2021.07.19 |

댓글